Warehouse shipping delays are a nightmare for any online store.

You work hard to get customers to hit that “buy” button, but if their order takes too long to arrive, it can all go downhill fast. Shoppers get frustrated, leave bad reviews, and maybe even never buy from you again.

In fact, 69% of customers say they won’t shop with a brand again if their order is late. That’s a huge deal. So, why do warehouse shipping delays happen? And, what can you do to stop them before they hurt your business?

Here’s what we’ll cover so you can avoid warehouse shipping delays in the future:

- The real cost of warehouse shipping delays on customer satisfaction, cart abandonment, and operational costs.

- Common causes of shipping delays, including inventory issues, incorrect addresses, and carrier bottlenecks.

- Proven strategies to avoid delays, such as automation, multi-origin shipping, and real-time tracking.

- How ShipperHQ can help eCommerce businesses streamline warehouse shipping and improve efficiency.

The Cost of Warehouse Shipping Delays

Shipping delays aren’t just an inconvenience. They directly affect your customer experience, revenue, and operations. Here’s how:

1. Customer Satisfaction Drops

Late deliveries frustrate customers. They leave negative reviews, demand refunds, and stop buying from you. In the age of online reviews, shipping delays can damage your brand reputation.

2. Higher Cart Abandonment Rates

Shipping speed matters. One in four shoppers will abandon their cart if the estimated shipping time is too long. If your competitor offers faster delivery, they win the sale.

3. Increased Operational Costs

Shipping delays lead to reshipping fees, extra customer service costs, and potential inventory losses. Managing refunds, dealing with returns, and handling chargebacks cut into your profits.

Avoiding shipping delays is essential for the brand’s success. But what causes them in the first place?

Why Do Shipping Delays Happen?

Now that we know how shipping delays hurt your business, let’s talk about why they happen in the first place.

1. Poor Inventory Management

If you don’t have real-time inventory tracking, you might oversell products you don’t actually have. This leads to backorders, delays, and customer complaints.

2. Slow Order Processing

Even if you have inventory, but your warehouse is disorganized or your team is stuck using slow, manual processes, orders won’t get out the door fast enough.

3. Carrier Delays

Sometimes, it’s not your fault – your shipping carrier drops the ball. Bad weather, package volume overload, and strikes causing worker shortages can all cause unexpected slowdowns.

4. Inaccurate Address Information

Wrong shipping addresses lead to failed deliveries, return shipments, and unhappy customers. In addition, you’d end up paying hefty address correction charges.

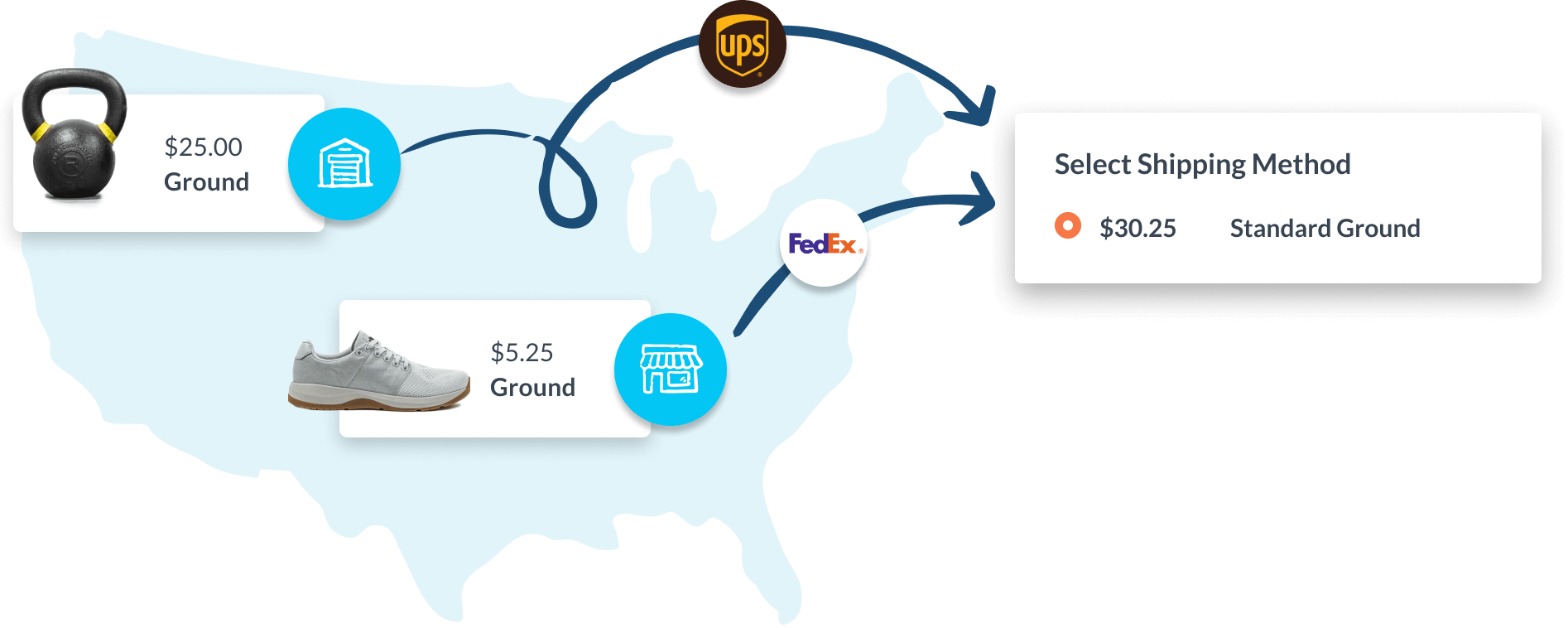

5. Single-Origin Shipping

If all orders ship from a single warehouse, customers far from that location experience longer transit times.

Strategies to Avoid Warehouse Shipping Delays

Alright, now that we’ve tackled the causes, let’s talk solutions.

1. Track Your Inventory in Real-Time

An inventory tracking system keeps stock levels accurate, so you don’t accidentally sell what you don’t have. Syncing inventory across all sales channels prevents overselling.

2. Speed Up Order Processing

Make sure your warehouse is organized and efficient. Automated picking and packing tools help move orders out the door faster.

3. Work With Multiple Carriers

Relying on just one shipping partner is risky. Partner with multiple carriers to ensure backup options when delays occur.

4. Validate Address Types

Use an address verification system to catch typos or incorrect address types before shipping. This cuts down on returns and lost packages.

5. Improve Last-Mile Delivery

Give customers real-time tracking so they know exactly when to expect their package. If possible, offer local delivery options to speed things up.

6. Ship From Multiple Locations

Distributing inventory across multiple fulfillment centers ensures customers receive their orders faster. By routing orders to the nearest warehouse, you can cut down shipping times and costs.

How ShipperHQ Optimizes Shipping Operations

Efficiently managing warehouse shipping operations demands intelligent, data-driven solutions that optimize speed, accuracy, and cost. That’s where ShipperHQ comes in. With a suite of powerful features, we help eCommerce retailers eliminate delays and improve shipping performance. Here’s how:

- Precise Delivery Dates: Show customers accurate delivery dates at checkout, so they know exactly when to expect their package.

- Optimize Order Fulfillment: Route orders from the nearest warehouse, cutting down transit times and reducing shipping costs.

- Ensure Accurate Delivery Addresses: Protect your margins and sales with correct charges for residential and commercial shipments.

- Leverage Shipping Data: Understand your shipping data and make informed decisions to improve your shipping experience.

Spotting what’s slowing down your warehouse shipping is half the battle. The other half is fixing it before it costs you sales and customers.

Looking for a smarter way to optimize your warehouse shipping?

Explore how ShipperHQ can help simplify your shipping operations and keep your eCommerce business moving fast.