Shipping costs are rising fast. From rate increases to surcharges and supply chain disruptions, eCommerce retailers are feeling the pinch in their margins. If you’re looking to stay competitive while offering the fast, convenient delivery options your customers expect, it’s time to rethink your fulfillment strategy.

That’s where store fulfillment steps in as a game-changing strategy. By turning your brick-and-mortar stores into mini-distribution hubs, you can bring products closer to customers, speed up delivery, and slash shipping expenses. Sounds promising, right?

Let’s unpack what store fulfillment means, how it helps cut costs, and how to measure whether it’s actually working for your business.

TLDR –

Store fulfillment helps eCommerce retailers cut shipping costs and speed up delivery by using nearby stores to fulfill online orders. It shortens delivery routes, reduces last-mile expenses, and unlocks convenient options like curbside and Buy Online Pickup In-Store (BOPIS). This approach turns physical stores into powerful fulfillment hubs.

Retailers benefit from better inventory utilization, faster fulfillment times, and improved customer satisfaction. By positioning stock closer to where customers live, store fulfillment creates a flexible, cost-effective strategy that scales with demand and boosts overall delivery efficiency.

What Is Store Fulfillment and Why It Matter

Store fulfillment means using your physical retail stores to fulfill online orders. Instead of shipping everything from a central warehouse, you fulfill orders directly from the nearest store with available stock.

This approach has gained serious traction as retailers look for ways to improve delivery times and lower shipping costs. The logistics world is shifting—from centralized to decentralized fulfillment, where products are stored and shipped from multiple locations closer to the customer.

Why Retailers Are Leaning In

Here’s why eCommerce retailers – especially those with physical locations – are embracing store fulfillment:

- Lower shipping costs by shortening delivery distances

- Faster deliveries, improving customer satisfaction

- More inventory flexibility, reducing the risk of overstock or stockouts

- Improved conversion rates, especially with accurate delivery estimates at checkout

Therefore, it’s a smart, scalable way to stay competitive in today’s retail landscape.

How Store Fulfillment Helps Reduce Shipping Costs

Let’s get into the practical stuff. Here’s how store fulfillment can help you bring down shipping costs.

1. Inventory Positioning Based on Demand

Having inventory close to where your customers live makes a huge difference. Instead of shipping across zones (which gets expensive fast), you can fulfill from the closest store, cutting down both time and cost.

With the right shipping strategy in place, you can even automate where orders get fulfilled based on zip code or delivery speed.

2. Adopting Ship-from-Store (SFS) Models

Your retail stores can become powerful micro-fulfillment centers. This strategy, known as ship-from-store, helps you make the most of your store footprint while reducing dependency on centralized warehouses.

It also helps clear out in-store inventory that may not be moving as fast, keeping products flowing and fresh.

3. Zone Skipping and Last-Mile Efficiency

Shipping across multiple zones increases costs fast. But when you use store fulfillment, you skip over many of these zones.

You also improve last-mile delivery, which is usually the most expensive leg of shipping. Getting products closer to the customer means fewer handoffs and less fuel, time, and labor spent.

4. Curbside and In-Store Pickup (BOPIS)

Encouraging customers to pick up their orders can eliminate shipping costs entirely. It also provides a better experience for customers who want flexibility and speed.

Bonus: Store pickup can help drive additional foot traffic and impulse purchases in-store.

KPIs to Measure the Success of Store Fulfillment

You can’t improve what you don’t measure. Here are the most important KPIs to track if you want to know whether your store fulfillment strategy is actually working.

1. Shipping Cost Per Order

This is your north star. By comparing average shipping costs before and after implementing store fulfillment, you can see the real cost savings.

Look for downward trends. If costs are going down, you’re on the right track.

2. Order Fulfillment Time

How fast can you process, pack, and deliver an order?

Tracking order fulfillment time – from the moment an order is placed to when it lands on the customer’s doorstep – helps you understand how efficient your store-based strategy is.

3. Inventory Turnover and Sell-Through Rates

If your store inventory is just sitting there, it’s a cost center. But if it’s helping fulfill online orders, you improve sell-through rates and reduce aging inventory.

Tracking how quickly products move at each location will show you whether your store network is being fully utilized.

4. Order Accuracy and Return Rate

Fulfilling orders from stores can introduce new challenges, especially if staff aren’t trained.

Keep an eye on order accuracy rates and return percentages to make sure your store staff is picking, packing, and shipping the right products. Mistakes can be costly and lead to unhappy customers.

Challenges to Watch For

No strategy is without hurdles. Store fulfillment works, but it requires thoughtful execution. Here’s what to plan for:

1. Balancing Online and In-Store Demand

If your store is fulfilling online orders, how do you make sure in-store shoppers don’t see empty shelves?

You’ll need to plan inventory smartly, setting aside a portion for in-store customers and another for online orders.

2. Staff Training and Operational Readiness

Store employees are trained for customer service, not logistics. Adding fulfillment responsibilities means training them on new processes, packing procedures, and shipping systems.

Tip: Start with pilot stores before rolling it out chain-wide.

3. Inventory Visibility

This is big. If your systems don’t reflect real-time stock levels, you’re setting yourself up for overselling and customer frustration.

Invest in tools that give you accurate, real-time inventory visibility across all store locations.

Streamlining Store Fulfillment with Multi-Origin Shipping Solutions

What Is Multi-Origin Shipping?

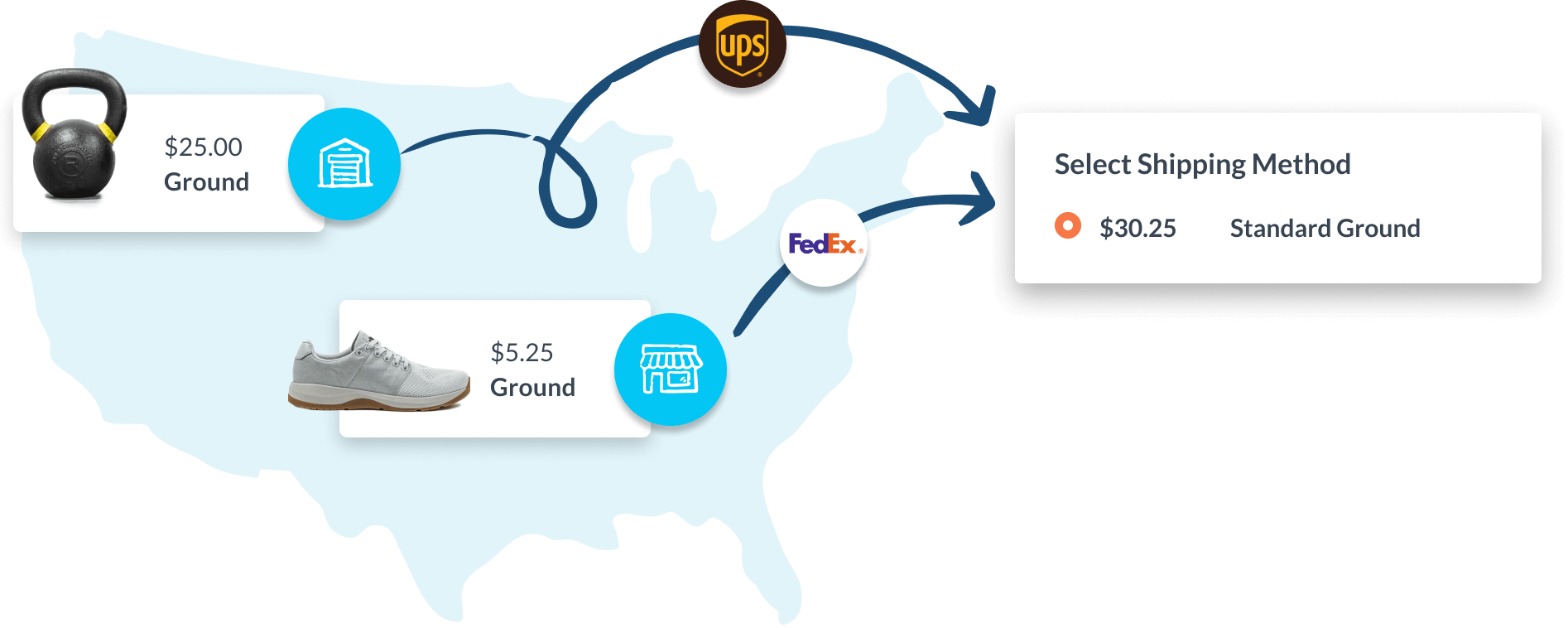

Multi-origin shipping allows ecommerce retailers to fulfill orders from multiple locations – whether that’s a warehouse, third-party logistics (3PL), or retail store.

Instead of guessing which location to ship from, multi-origin logic automatically routes orders based on factors like inventory, cost, distance, and delivery speed.

How ShipperHQ Supports Store Fulfillment

ShipperHQ’s advanced shipping rules and carrier integrations make this possible. With ShipperHQ, you can:

- Automatically calculate real-time shipping rates from different origins

- Show customers accurate delivery times and costs at checkout

- Prioritize fulfillment from the most efficient location, whether that’s a store or warehouse

- Route split shipments smartly from the most efficient location

- Display store pickup options where applicable

Benefits for Retailers

With ShipperHQ’s multi-origin shipping capabilities, you can:

- Reduce cart abandonment by offering reliable, cost-effective delivery options.

- Improve margins by avoiding unnecessary shipping fees

- Deliver faster by fulfilling from the location closest to the customer

- Gain operational flexibility, letting your team focus on scaling, not juggling spreadsheets.

Retailers who adopt store fulfillment aren’t just improving delivery speed—they’re gaining a serious edge in cost efficiency, customer satisfaction, and operational agility.

Ready to see how store fulfillment can transform your shipping and fulfillment operations?

Start your free trial of ShipperHQ and see how easy it is to cut shipping costs, speed up delivery, and scale your business – without the headaches.