The U.S. Less-Than-Truckload (LTL) market is projected to grow significantly, reaching $139.63 billion by 2030 with a compound annual growth rate (CAGR) of 4.19%.

This growth underscores the increasing reliance on LTL freight rates as retailers aim to balance cost-effectiveness with efficiency. However, navigating the complexities of LTL shipping is essential to optimize your strategy.

In this blog, we will look at the top five factors that affect LTL freight rates. We will also give you useful tips to help you manage costs while keeping service quality high.

What Are LTL Freight Rates?

LTL freight refers to shipping goods that don’t require a full truckload. Instead, businesses share trailer space, making it a cost-effective option for smaller shipments. Rates are determined by factors such as shipment size, weight, and destination.

Unlike Full Truckload (FTL) shipping, where you pay for the entire truck, LTL freight charges only for the space your shipment occupies. This flexibility makes it a preferred choice for many eCommerce businesses.

By understanding how these rates are calculated, businesses can make smarter decisions, cut costs, and enhance shipping efficiency. Let’s examine the factors that influence LTL freight rates.

#1 Freight Class

Freight class is a key determinant of LTL freight rates. The National Motor Freight Traffic Association (NMFTA) assigns freight classes based on four attributes:

- Density: Weight relative to size.

- Stowability: How easily the freight can be loaded with other shipments.

- Handling: Level of care required during transport.

- Liability: The shipment’s value and risk of damage or theft.

Freight classes range from 50 (cheapest) to 500 (most expensive). Lightweight, high-volume goods often fall into higher classes, resulting in increased rates.

Tip: Always classify shipments accurately to avoid reclassification fees, which can lead to unexpected charges and delays.

#2 Shipment Dimensions and Weight

Accurate dimensions and weight are critical for determining LTL freight rates. Carriers use these details to calculate the space your shipment will occupy and its impact on capacity and fuel usage.

Dimensional weight, or DIM weight, is particularly important. It factors in the shipment’s size relative to its weight, penalizing lightweight but bulky shipments.

Tips to Manage Costs:

- Use precise scales and measuring tools to ensure accuracy.

- Avoid over-packaging, which increases shipment size and cost.

Carriers may remeasure your shipment if they suspect discrepancies, potentially leading to additional charges. By providing accurate details upfront, you can avoid unnecessary fees.

#3 Shipping Distance

The distance between your shipment’s origin and destination significantly impacts costs. Longer distances require more resources, increasing rates.

Carriers segment regions into shipping zones, and moving goods between distant zones generally raises prices.

Strategies to Reduce Costs:

- Optimize your warehouse locations to minimize shipping distances.

- Leverage regional carriers for shipments within specific zones.

- Use a shipping management platform to identify cost-efficient routes.

By strategically managing your shipping network, you can reduce transit times and associated costs.

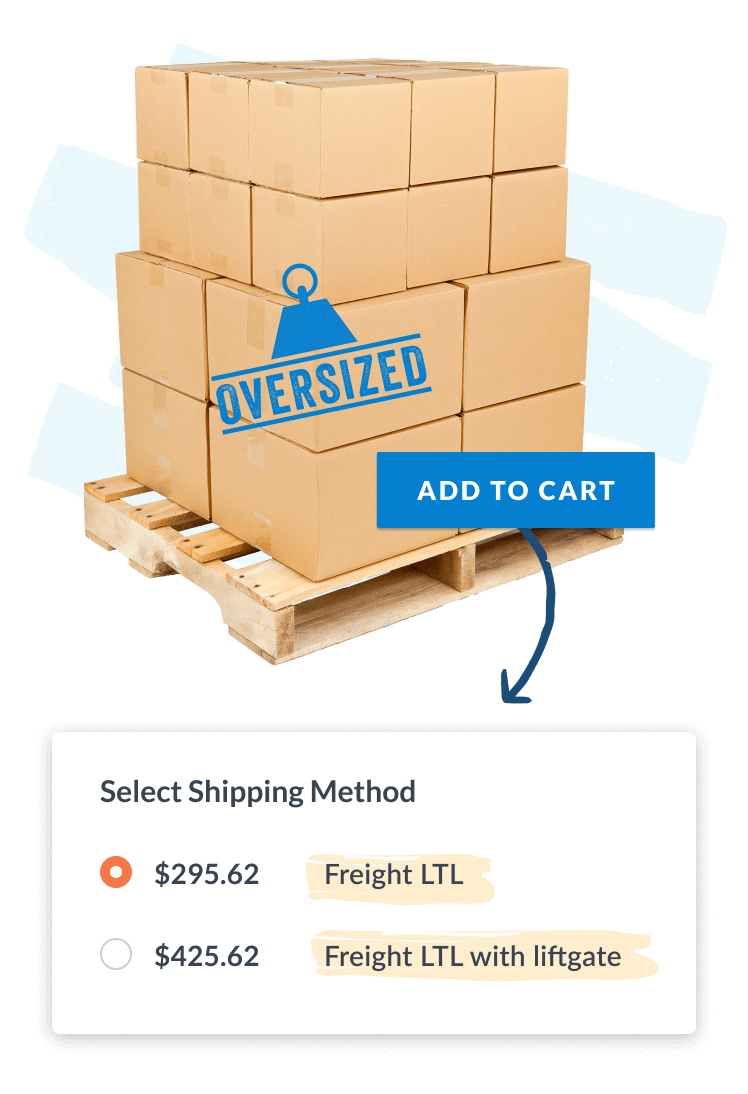

#4 Accessorial Charges

Accessorial charges are additional fees for services beyond standard pickup and delivery. Examples include:

- Liftgate delivery: Required when a forklift is unavailable for heavy shipments.

- Inside delivery: Delivering goods beyond the curbside.

- Limited access locations: Deliveries to places like schools, construction sites, or rural areas.

While these services enhance convenience, they can significantly inflate the shipping costs.

Tips to Avoid Excessive Fees:

- Clearly communicate service requirements to carriers upfront.

- Plan deliveries to avoid unnecessary accessorial services.

- Use a freight broker to negotiate better terms for recurring services.

Predictable planning reduces the impact of these charges.

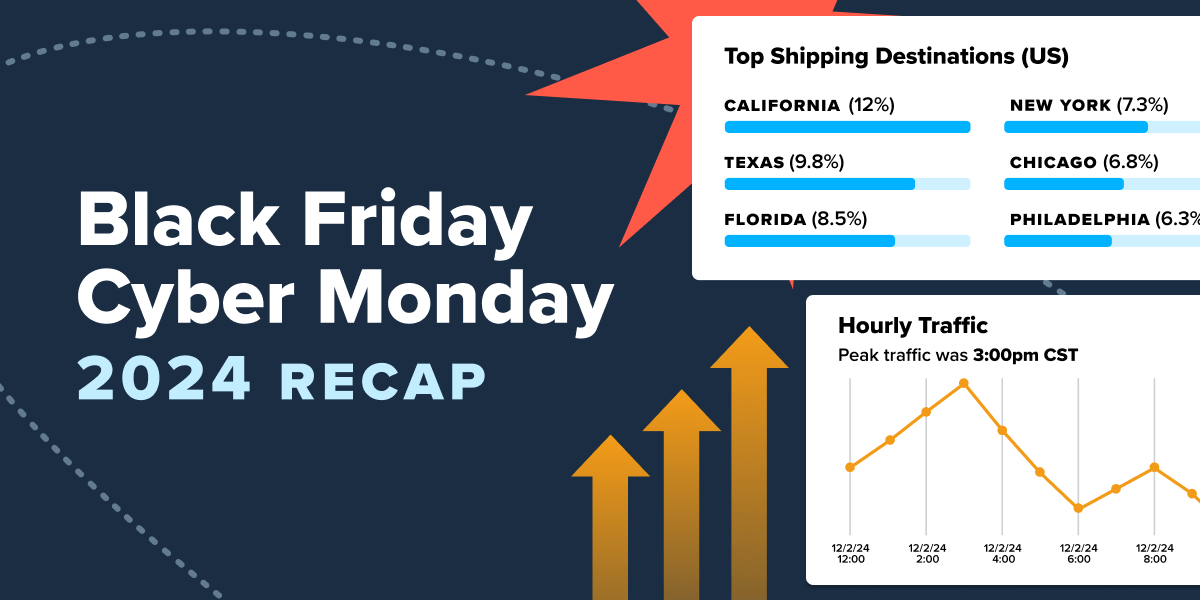

#5 Freight Volume and Capacity

Market demand and capacity constraints also affect LTL freight rates. During peak seasons, carriers often face high demand, leading to rate increases.

How to Manage This Challenge:

- Consolidate shipments to maximize trailer space and lower per-unit costs.

- Ship early during peak seasons to avoid surcharges.

- Stay informed about market trends to anticipate price fluctuations.

Booking shipments in advance and offering flexible delivery windows can help mitigate costs.

Tips to Control Your LTL Freight Costs

Understanding the factors influencing LTL freight rates is just the first step. Here are actionable tips to keep your shipping costs in check:

- Partner with Reliable Carriers: Build relationships with carriers offering consistent rates and reliable service.

- Leverage a Shipping Management Platform: Shipping management platforms like ShipperHQ streamline rate comparisons, helping you find the best deal.

- Consolidate Shipments: Combining smaller shipments into fewer loads can significantly reduce costs.

- Review Contracts Regularly: Evaluate your shipping contracts to ensure you’re benefiting from competitive rates.

- Optimize Packaging: Reducing package size and weight lowers DIM weight charges.

By adopting these strategies, businesses can achieve significant cost savings while maintaining high service standards.

Mastering LTL Freight Rates to Optimize Costs

Freight pricing can be complex, but a solid understanding of LTL rates allows retailers to optimize their shipping strategies. By focusing on freight class, dimensions, distance, and accessorial charges, businesses can minimize costs and improve efficiency.

At ShipperHQ, we empower eCommerce retailers to streamline LTL shipping. From optimizing rates to enhancing customer experiences, our platform helps you make smarter decisions.

Take control of your shipping costs today—start your 15-day free trial of ShipperHQ!